Natančna tipala za merilne aplikacije

Renishaw je pripravil celovito ponudbo natančno izdelanih tipal za meritev. Odkrijte, zakaj je prav kakovost tipal in pribora ključnega pomena v industrijski merilni tehniki in kakšno podporo vam zagotavlja Renishaw.

Natančna tipala Renishaw

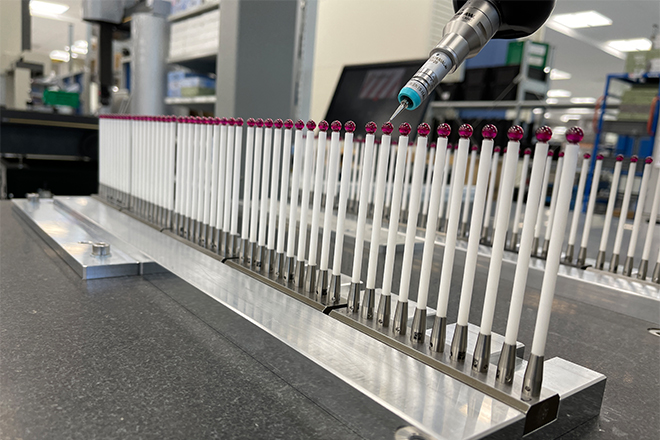

Tipala za merilne sisteme Renishaw za KMS, obdelovalne stroje, skenirne glave in merilni sistem Equator™.

Vaš partner za natančnost že 50 let

Natančna tipala dopolnjujejo merilne sisteme iz Renishawa za optimalno zmogljivost. V naši standardni ponudbi je več kot 500 delov, različice po meri pa so na voljo po naročilu. Imamo tudi obsežno in izkušeno omrežje aplikativnih inženirjev, ki vam lahko ponudijo celovito tehnično podporo ter vas vodijo pri izbiri in uporabi tipal za vašo edinstveno aplikacijo.

Renishaw dobavlja tipala za različne aplikacije, zagotavlja pa tudi združljivost z merilnimi glavami ZEISS in FARO®. Če želite izvedeti več o naši ponudbi tipal za merilne glave ZEISS in FARO, si oglejte našo stran natančno izdelana tipala.

Tipala iz našega obsežnega programa so primerna za različne sisteme. Med njimi so tudi merilni sistemi Renishaw za KMS, obdelovalne stroje, skenirne glave in merilni sistem Equator™. Uporabljate jih lahko tudi z merilnimi glavami drugih proizvajalcev.

Renishaw je razvil diamantna tipala OPTiMUM™ za vse bolj razširjene aplikacije visokohitrostnega skeniranja. Odkrijte, zakaj kroglice z diamantno prevleko ostanejo okrogle in niso podvržene nalaganju materiala ali prezgodnji obrabi med skeniranjem delov.

Če v naši obsežni ponudbi standardnih izdelkov ne najdete prave rešitve, vam lahko tipala po meri razvije hišna ekipa konstruktorjev pri Renishawu. Za vas lahko konstruiramo tipala po meri vaše specifične aplikacije.

Dodajalna izdelava je prilagodljiva in zmogljiva tehnologija, s katero je mogoče ustvariti tudi takšne kovinske komponente in dele, kjer bi tradicionalni izdelovalni postopki odpovedali. Odkrijte, zakaj 3D-natisnjena tipala zagotavljajo več možnosti meritev kot kadar koli prej.

Vaš partner za rešitve v avtomobilski proizvodnji

Množična proizvodnja avtomobilskih komponent v veliki meri sloni na ponovljivih procesih kontrole in zagotavljanja kakovosti.

Morda se zdi, da so tipala na merilnih glavah za kontrolo manj pomemben element procesa, vseeno pa so ključnega pomena za meritve, saj pridejo v stik z merjenci ter omogočajo premikanje merilnega mehanizma in zajem merilnih signalov.

Pri Renishawu upoštevamo vse podrobnosti, kot je pravilna uporaba merilnih glav. Pri izbiri tipal je treba upoštevati lastnosti in material, iz katerega so izdelani merjenci. Pomembna je tudi vrsta merilnega sistema. Lastnosti tipal, kot so material, velikost, togost in okroglost, lahko znatno vplivajo na zmogljivost meritev in na zahteve glede vzdrževanja sistemov.

Zakaj postati Renishawov kupec?

Kakovost tipal in pribora ima ključno vlogo pri industrijskih meritvah. Z našimi tipali prejmete tudi naše zaveze:

- Standardna ponudba več kot 500 delov in več kot 15.000 različic po meri.

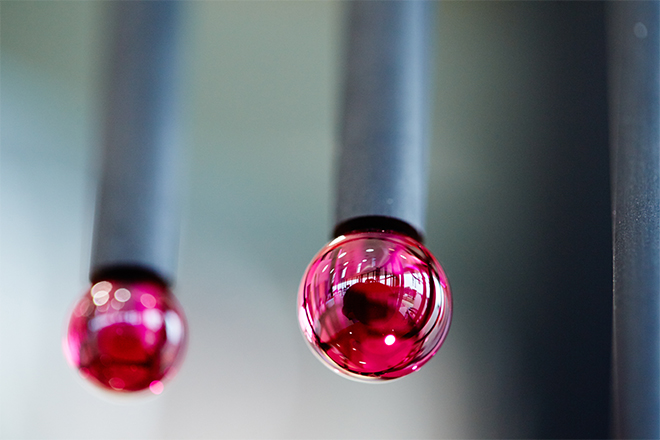

- Kroglice v vrhunski kakovosti. Standardno razreda 5 (okroglost 0,13 mikrona), po naročilu razreda 3 (okroglost 0,08 mikrona).

- Široka paleta kombinacij materialov.

- Obsežno omrežje izkušenih aplikativnih inženirjev, ki vam lahko ponudijo celovito tehnično podporo ter vas vodijo pri izbiri in uporabi tipal za vašo edinstveno aplikacijo. To vključuje pripravo aplikacije, svetovanje glede meritev in izbor materialov.

- Prodajno in podporno omrežje po vsem svetu s pisarnami v 36 državah.

- Zaloga v skladiščih po vsem svetu za hitro lokalno dobavo.

- Spletna prodaja v 9 trgovinah po svetu.

Kako naročiti

V naši spletni trgovini lahko naročate 24 ur na dan. Nakupujte prek spleta ali pa se obrnite na lokalne komercialiste.

Obiščite našo spletno trgovino in izberite tipalo v naši obsežni ponudbi standardnih rešitev.

Če ne najdete pravega tipala, oddajte obrazec za povpraševanje za tipala po meri.

Kaj je tipalo?

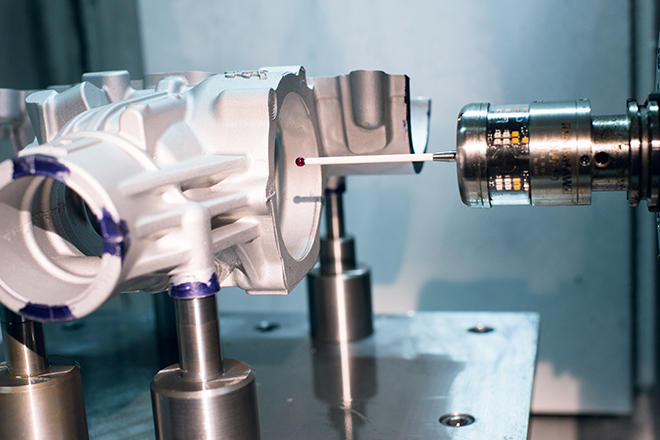

Tipalo je del merilnega sistema, ki pride v stik s komponento in povzroči premik mehanizma merilne glave. Pri tem nastane signal, ki omogoči meritev.

Tipalo je prva vez z obdelovancem. Zato je pomembno, da tipalo v točki stika zagotavlja največjo točnost.

Vrsta in velikost tipala sta odvisni od kontrolirane značilnosti. V vsakem primeru pa sta ključni maksimalna togost tipala in popolna sferičnost konice.

Pomen tipal za natančnost

Uspešno merjenje je odvisno predvsem od dostopa merilnega tipala do merjenca in njegove točnosti v stični točki.

Zmogljivost vašega merilnega sistema se lahko hitro izgubi, če okroglost kroglice tipala ni zadovoljiva, če kroglica ni v pravi legi, se ne ujema navoj, ali pa se tipalo zaradi neustrezne zasnove preveč upogiba med merjenjem.

Pri Renishawu uporabljamo svoje znanje na področju konstruiranja merilnih glav in tipal za razvoj celovite ponudbe tipal za koordinatne merilne stroje in merilne glave za obdelovalne stroje, ki vam prinaša največjo možno natančnost.

Tipala Renishaw za aplikacije z merilnimi sistemi ZEISS in rokami FARO®

Renishaw je razširil svoj obsežni katalog tipal s tipali, adapterji in priborom za merilne glave ZEISS in FARO.

V naši ponudbi je bogat izbor ravnih tipal v raznih materialih in velikostih navoja, kakor tudi pestra ponudba tipal v obliki zvezde, diska in drugih, s katerimi boste lahko izpolnili zahteve svojih aplikacij z merilnimi glavami ZEISS.

V ponudbi tipal za roke FARO so tipala s kroglico iz cirkonijevega dioksida in tipala s konico iz volframovega karbida z različnimi velikostmi navojev in z izborom pribora za potrebe različnih aplikacij.

Tipala Renishaw za aplikacije z merilnimi glavami ZEISS in rokami FARO ®

Ponudba tipal Renishaw za merilne glave ZEISS in merilne glave za roke FARO.

Servis in podpora

Širitev družbe Renishaw v zadnjih 50 letih so vedno spremljale naložbe v globalno prodajno in podporno omrežje. Danes ga sestavljajo pisarne v več kot 36 državah ter globalno omrežje distributerjev in zastopnikov.

Za naše stranke to pomeni, da je na raznih lokacijah po svetu v vsakem trenutku na voljo več kot 100.000 tipal, s čimer je zajamčena hitra lokalna dobava.

S svojo zavezo odličnim storitvam in podpori za stranke smo si pridobili zavidljiv ugled. Če potrebujete tehnični nasvet ali naletite na težavo, je v vsakem trenutku na voljo naše globalno omrežje strokovnjakov, ki vam bodo ponudili nasvet in priporočili primerno zamenjavo.

Pomembni namigi v zvezi z uporabo tipal:

- Uporabljajte originalna tipala Renishaw.

- Vedno izberite čim krajša in čim bolj stabilna tipala.

- Uporabite največjo možno kroglico.

- Ali uporabljate komponente, ki so termično stabilne? Upoštevajte pogoje okolice.

- Pri sestavljanju konfiguracij tipal upoštevajte dovoljeno skupno maso po specifikacijah proizvajalca merilne glave.

- Uporabite najmanjše možno število posameznih komponent.

Izobraževalni vodič za natančna tipala

V vodiču boste našli najpomembnejše tehnične informacije v zvezi z izbiro in uporabo ustrezne vrste tipal, materiali, konstrukcijo in umerjanjem.

Pogosto zastavljena vprašanja in odgovori

Oglejte si pogosto zastavljena vprašanja o tipalih Renishaw.

Zakaj obstajajo različne vrste tipal?

Obsežna ponudba pristnih tipal Renishaw vključuje številne konfiguracije, ki so primerne za različne merilne aplikacije. Vse komponente so na voljo v različnih materialih, vključno s kroglicami tipal. Za več informacij si prenesite naš Vodič za natančna tipala.

Kako lahko prepoznate originalno tipalo Renishaw?

Večina naših tipal ima na držalu natisnjen logotip Renishaw. Vsa tipala so dobavljena v plastičnih škatlah, ki so opremljene z nalepkami s hologramom. Da bi zagotovili integriteto zbranih podatkov, naročite in uporabljajte izdelke iz celovite ponudbe originalnih tipal Renishaw.

Ali so tipala Renishaw skladna z Direktivo RoHS?

Ponudba tipal je skladna z Direktivo RoHS. Preberite našo celotno izjavo.

Povežite se z našimi komercialisti

Stopite v stik z lokalnim zastopništvom za več informacij in za pogovor s strokovnjakom.