Kaj je umerjanje

Izvedite, kako delujejo izdelki za umerjanje in kako vam lahko pomagajo izboljšati procese.

Umerjanje je temelj nadzora procesov

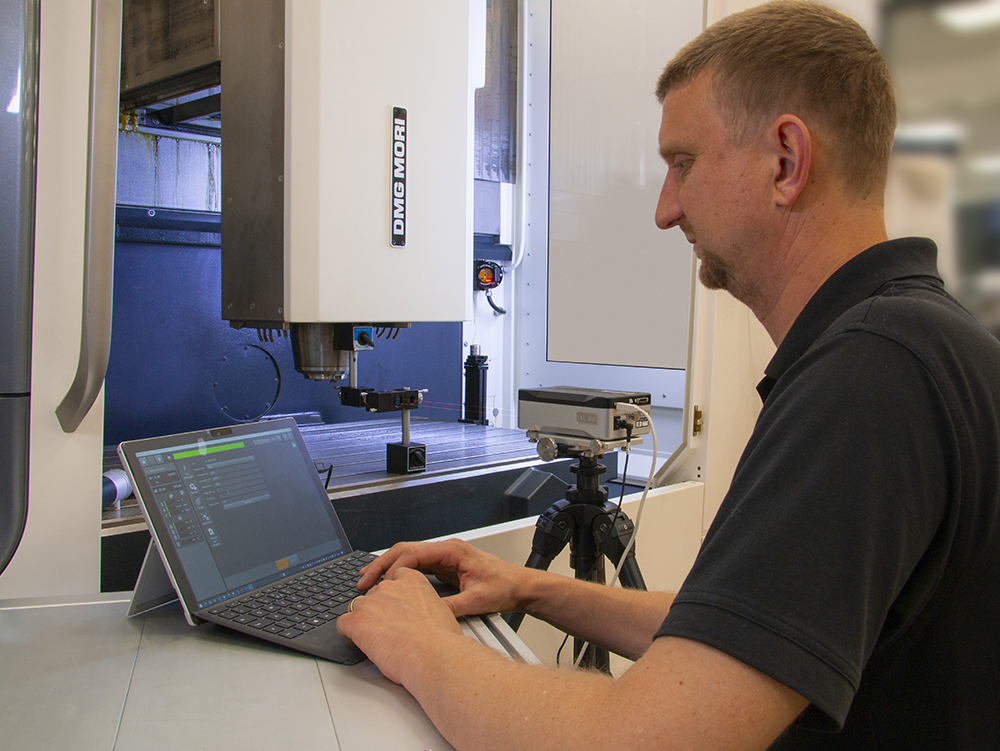

Sodobna industrija operira z vedno ožjimi tolerancami, krajšimi dobavnimi roki in v skladu z zahtevami mednarodnih standardov kakovosti. Zmogljivost opreme ob upoštevanju stroškovnih pritiskov še nikoli ni bila pomembnejša.

Izdelki za umerjanje in optimizacijo strojev iz Renishawa omogočajo preizkušanje in diagnostično obravnavo med gradnjo, proizvodnjo in zagonom strojev za ohranitev visoke točnosti in skrajšanje zastojev v obratovanju.

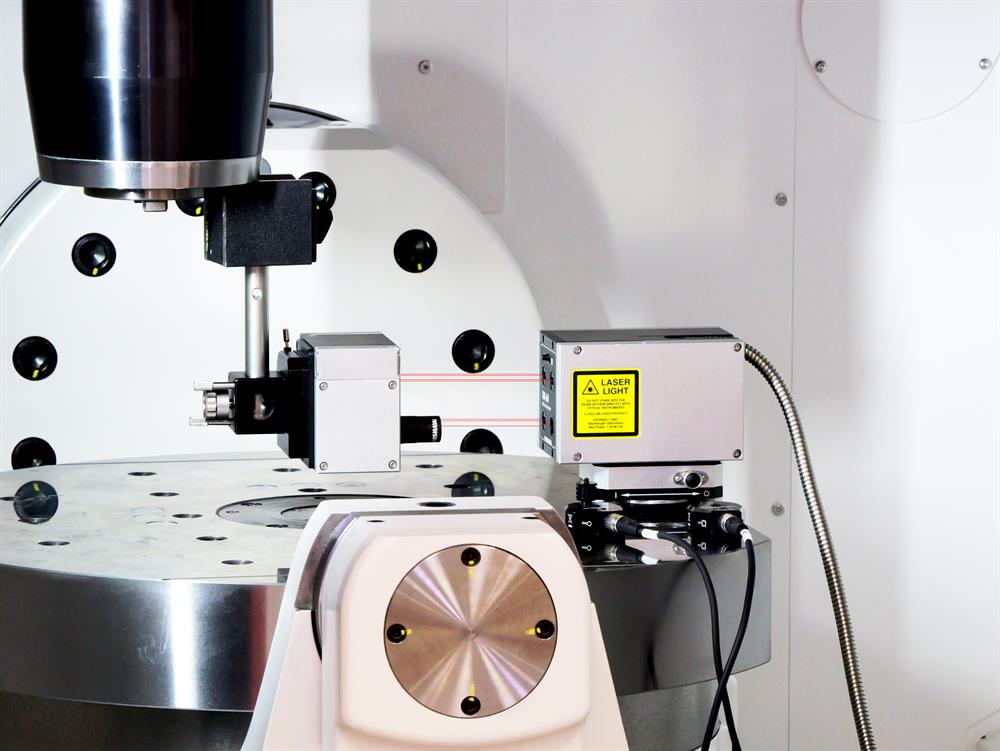

Kaj je interferometrija

Laserska interferometrija je uveljavljena metoda za merjenje razdalj z visoko natančnostjo. Seznanite se z osnovami laserske interferometrije in zakaj je to lahko najbolj točna in ponovljiva metoda umerjanja.

Osnove preskušanja z ballbarom

Zasluge za priljubljenost preizkušanja z ballbarom gredo enostavnosti preizkusa, hitrosti uporabe in veliki množini pridobljenih uporabnih kvantitativnih informacij. Izvedite več o pripravi testov z napravo QC20 ballbar, zajemu podatkov in analizi.

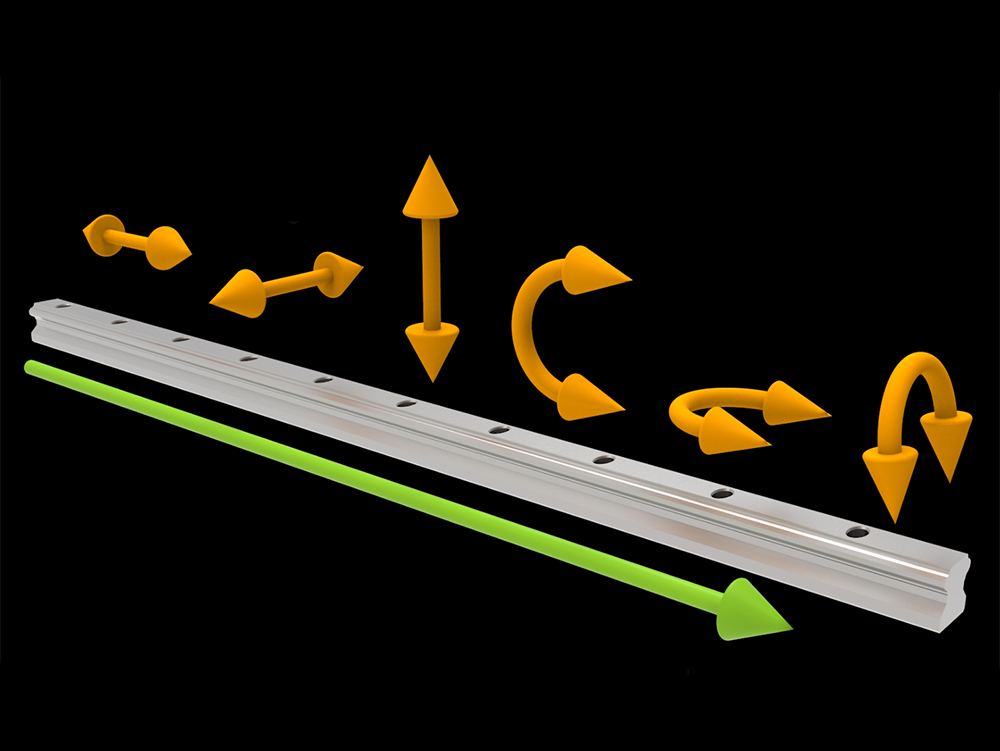

Kaj pomeni šest prostostnih stopenj

Večosni kalibrator XM-60 omogoča hkratno in neposredno meritev vseh šestih napak v poljubni smeri gibanja.

Oglejte si video z razlago različnih vrst napak na linearni poti gibanja.

Študije primerov

Odkrijte, kako so bile naše tehnologije za lasersko umerjanje in ballbar uporabljene za optimizacijo zmogljivosti v različnih industrijah.

Preberite več o koristih, ki jih rešitve za umerjanje prinašajo našim kupcem.